Beyond Mining: The Diverse Applications of Heavy-Duty Tire Chains in Industrial Settings

Heavy-duty tire chains are synonymous with the rugged demands of mining. These specialized chains provide vital protection and traction for large, expensive tires that endure some of the harshest conditions on Earth. However, the utility of heavy-duty tire chains extends far beyond mining operations. Construction, forestry, and waste management industries rely on these durable chains to improve safety, efficiency, and tire longevity. This article explores the diverse applications of heavy-duty tire chains in various industrial settings, shedding light on their critical role in ensuring operational success in challenging environments.

Understanding Heavy-Duty Tire Chains

Heavy-duty tire chains, or tire protection chains, are crafted from high-grade steel and designed to withstand extreme conditions. They cover the surface of tires, offering a shield against sharp rocks, abrasive materials, and other hazards that can cause costly tire damage. These chains are not only about protection; they also enhance traction, allowing heavy machinery to navigate difficult terrains with greater ease. In industrial settings, where equipment downtime can result in significant financial losses, the use of tire chains becomes a strategic necessity.

Types of Heavy-Duty Tire Chains

Different industrial applications require specific types of tire chains. Understanding these variations helps in selecting the right chain for the job:

- Twist Link Chains: These chains are common in construction and forestry, providing a balance of protection and flexibility.

- Square Link Chains: Known for their durability, they offer superior traction, making them ideal for ice-covered or muddy terrains.

- Ladder-Style Chains: Designed for low-clearance vehicles, these chains are widely used in environments where space around the tire is limited.

Heavy-Duty Tire Chains in Forestry

Navigating Harsh Forest Terrains

Forestry operations take place in some of the most challenging terrains, from muddy swamps to snow-covered mountains. In these environments, tire traction is critical. Heavy-duty tire chains give logging equipment the grip it needs to operate safely and efficiently. Whether it’s a skidder hauling logs or a harvester maneuvering through dense underbrush, tire chains ensure that these machines maintain stability and control, even on the most slippery surfaces.

Preventing Environmental Damage

In forestry, the impact of machinery on the environment is a significant concern. Heavy-duty tire chains help mitigate this impact by distributing the weight of the vehicle more evenly across the ground. This reduces soil compaction, which can damage root systems and hinder plant growth. By choosing the right tire chains, forestry operators can balance the need for heavy equipment with environmental stewardship.

Heavy-Duty Tire Chains in Waste Management

Tackling Tough Waste Sites

Waste management facilities often operate in conditions that are highly abrasive and littered with sharp objects. Heavy-duty tire chains provide an essential layer of protection for the tires of garbage trucks, bulldozers, and other waste-handling machinery. These chains prevent tire damage from glass shards, metal debris, and other hazards commonly found at waste sites, ensuring that vehicles remain operational despite the harsh environment.

Reducing Maintenance Costs

Heavy-duty tire chains significantly reduce the frequency of tire repairs and replacements. This is particularly important in waste management, where equipment downtime can lead to a backlog of waste, regulatory fines, and other costly issues. By maintaining the integrity of tires, these chains help keep waste management operations running smoothly and efficiently.

Heavy-Duty Tire Chains in Quarries

Managing Rock and Debris

Quarry operations involve the constant movement of heavy machinery over jagged rocks and rough terrain. In these conditions, tires are highly susceptible to damage. Heavy-duty tire chains protect quarry equipment by absorbing the impact of sharp stones and preventing punctures. This protection allows machinery to operate at peak performance, even in the most unforgiving environments.

Improving Traction on Loose Surfaces

Loose gravel and dust-covered surfaces can be treacherous for heavy equipment in quarries. Heavy-duty tire chains enhance traction, preventing slippage and improving the stability of the machinery. This increased control not only improves safety but also enhances the efficiency of material handling and transport within the quarry.

Tire Chains in Agriculture

Operating in Wet and Muddy Fields

Agricultural operations often require machinery to operate in wet, muddy conditions, especially during planting and harvest seasons. Heavy-duty tire chains give tractors and other farm equipment the traction they need to navigate these challenging conditions without getting stuck. This ensures that agricultural activities can continue uninterrupted, regardless of the weather.

Protecting Against Soil Compaction

Like forestry, agriculture requires careful management of soil health. Heavy-duty tire chains help distribute the weight of heavy machinery more evenly, reducing soil compaction. This is particularly important for preserving the structure of the soil, which is vital for healthy crop growth. By using tire chains, farmers can balance the need for mechanization with the long-term health of their land.

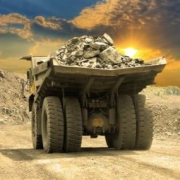

Heavy-Duty Tire Chains in Mining

Protecting Tires from Abrasive Materials

In mining, the terrain is often littered with sharp rocks, metal shards, and other abrasive materials that can quickly destroy unprotected tires. Heavy-duty tire chains serve as a vital defense, shielding tires from these hazards and preventing costly damage. The use of tire chains in mining not only extends tire life but also ensures that equipment can operate without interruption, even in the harshest conditions.

Enhancing Equipment Mobility

Mining operations often take place on steep, uneven terrain where traction is a constant challenge. Heavy-duty tire chains provide the necessary grip for machinery to move safely and efficiently. This improved mobility reduces the risk of accidents and allows mining operations to proceed smoothly, even in difficult conditions.

Choosing the Right Tire Chains

Factors to Consider

Selecting the right heavy-duty tire chains for your industrial needs involves several factors:

- Terrain: The type of terrain where the equipment will operate is crucial. For rocky, abrasive surfaces, more robust chains are required, while muddy or snowy conditions might necessitate chains with enhanced traction features.

- Vehicle Type: Different vehicles have different clearance requirements and weight distributions. Chains must be compatible with the specific vehicle to avoid interference with other components.

- Durability: The lifespan of the tire chain is also an essential consideration. Chains made from higher-quality materials will last longer but may come at a higher upfront cost.

Maintenance and Care

Proper maintenance of heavy-duty tire chains is vital to ensuring their longevity and effectiveness. Regular inspections for wear and tear, along with timely repairs, can prevent chain failure and extend their useful life. Additionally, storing chains in a dry, cool environment when not in use will prevent rust and other forms of corrosion.